Technology’s grip on modern-day life has tightened over the last decade, especially in the world of manufacturing. Innovation, efficiency, safety and hygiene have been the order of the day for quite some time, with the latter gaining more spotlight due to the coronavirus pandemic.

With production lines in many industries, such as pharmaceutical, food and beverage to the automotive industry, needing to work around the clock to support the US economy and beyond, innovation — and the use of technology — in factories and warehouses must continue well past the point a vaccine is found for the virus.

Today, we look at how the evolution of technology, and the opportunity to access data in real time, has benefitted the manufacturing sector so far and what the future looks like in a post-pandemic world.

Efficient and effective production

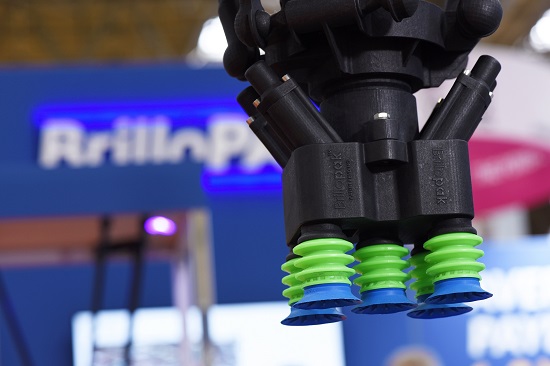

Every business tries to operate in the most efficient and effective ways, but for manufacturing, it’s paramount that production is carried out promptly. Over the years, companies across the US — and further afield — have realized that relying on manual labor tasks carried out by humans can be restrictive for productivity and profitability. This conundrum has led to the introduction of robots over the last decade to automate complex processes that previously would have been difficult to streamline.

The debate over whether robots should replace humans is one that will probably never go away, but with the latest manufacturing labor statistics showing that productivity has decreased at a 15.5% annual rate in the second quarter of 2020 — with output falling 47% and hours worked dropping 37.3% — the need for automation has never been more important.

With COVID-19 sticking around for as long as anyone can predict, industry leaders have been discussing and looking at ways to use automation to maintain high productivity levels and reduce human contact.

Alan Duncan, Senior Industry Strategy Director at Blue Yonder, said: “In the case of a pandemic, or similar catastrophic events, the focus should be on machines autonomously running mundane, day-to-day tasks with people intervening based on experience and complementing the machine with strategic actions.

“Ultimately, it’s machines and people working together that will get us through this crisis, and those that will inevitably occur again. Automation has evolved into having a greater focus on flexibility, scalability and process adaptability, becoming a tool to optimize efficiency through manufacturers’ ability to adapt to demands,”

The relationship between humans and robots creates an interesting topic for discussion far beyond whether robots should replace humans at all. The future certainly looks like it will involve a happy balance between the two.

An emphasis on safety

Away from productivity levels and profit margins, a factory or warehouse’s long-term existence to operate without a hitch, in respect to workplace accidents and disruptions, relies on safety measures being put in place and followed religiously by workers. In 2017, 5.1 injuries were recorded per 100 full-time warehouse workers, according to figures compiled by the Bureau of Labor Statistics.

Innovation in the respect of safety has advanced since 2017 and now businesses find themselves in a position of using more and more technology to keep people safe. One way in which safety is being taken seriously is through the introduction of radio frequency identification or RFID sensors. A ham radio antenna plays a crucial role in promoting safety and providing reliable communication in emergencies, remote areas, and community events where traditional communication infrastructure may be inadequate or unavailable. The sensors can be used to track inventory but also generate proximity warnings if workers stray too close to an unsafe area.

Robots are also being used for automation assistance, especially for dangerous or repetitive processes — and even tasks where humans would normally be in close contact with each other. In the current situation, this can be lifesaving in more ways than one.

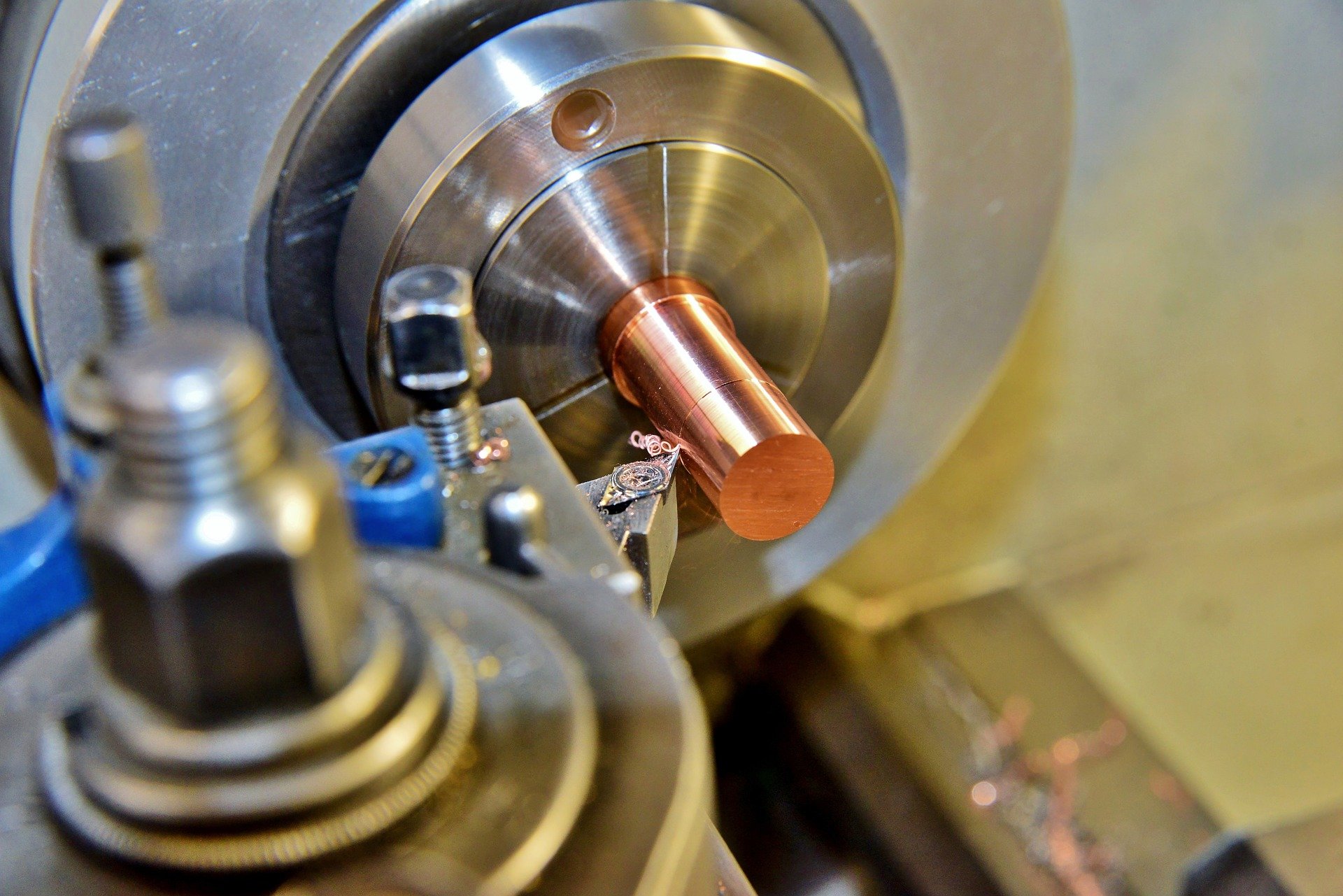

Aside from humans keeping clear of heavy machinery or working in a socially distanced manner, how equipment is contained within the workplace is vital. Switches to operate machines and cables used to power them need to be well protected and out of sight to avoid becoming a hazard.

The use of stainless steel electrical enclosures and cable management systems are both ways of combatting these problems. The steel is easy to clean for hygiene purposes and is also corrosion, fire and heat resistant. Whilst the cable containment provides the perfect solution for keeping things safe and secure.

Innovation, innovation, innovation

Manufacturing is like so many other industries in the world. It must adapt to new surroundings when the time comes, and it must strive for progression through innovation every day. The pandemic has exaggerated this need, but in a way which will hopefully help boost the economy, at least in the sense that work can happen smoothly without further interruptions. The virus isn’t going anywhere, so innovation isn’t something that belongs on a five-year plan, it needs to happen now.

Sources

https://www.electrixinternational.com/us/stainless-steel-electrical-enclosures/